If humans are going to live on Mars or the moon one day, we should be able to build buildings to live, sleep, eat and work in space. The way to do that, the space agency said, is to 3D print habitats or their components. But transporting several Earth-derived materials used for most 3D printing from our planet to another celestial body is not a feasible option.

Biology could solve this problem, he says Neil Joshi, associate professor of chemistry and chemical biology at Northeastern. And Joshi's team may have invented just the technology for the job: a 3D printing material that's alive.

“Just like a tree has cells built into it and it goes from a seed to a tree by absorbing resources from its environment to implement these structure-building programs, what we want to do is something similar, but where we provide these programs in the form of DNA that we writing and genetic engineering,” says Joshi.

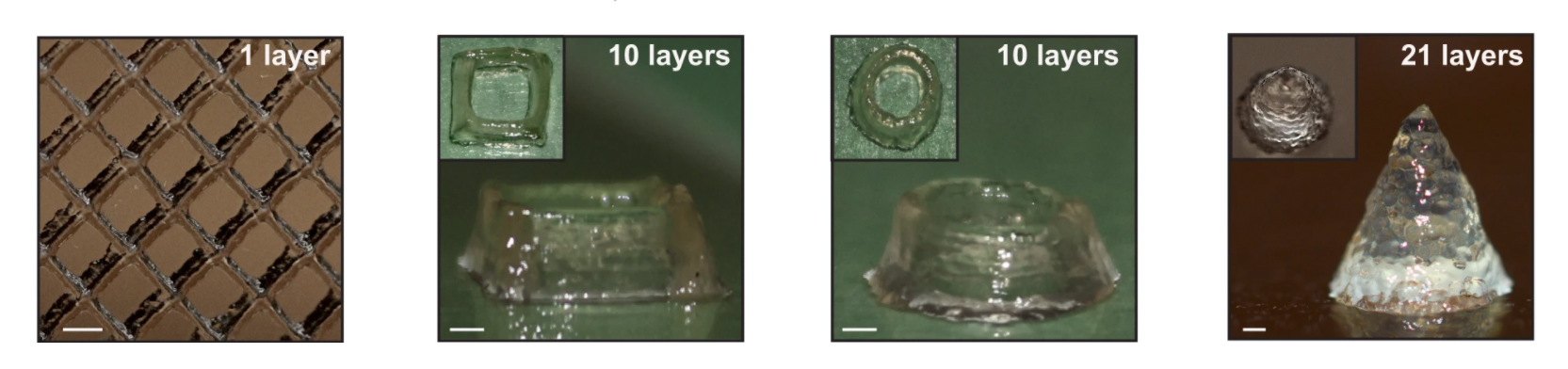

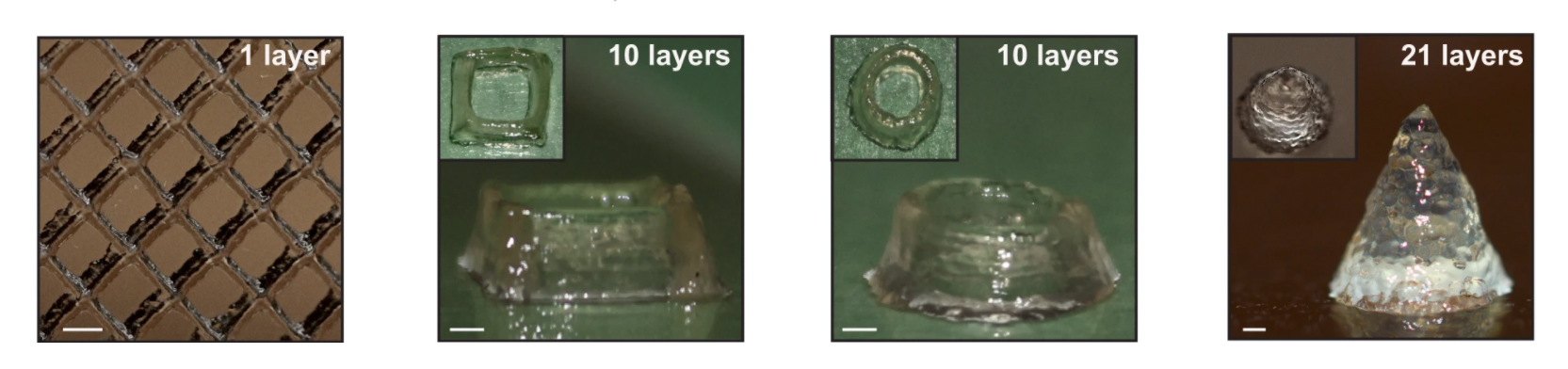

Researchers have figured out how to program the bacterium Escherichia colialso known as E. coli, to produce an entirely organic ink that can be used to 3D print solid structures. This microbial ink, which is described in a paper published Tuesday in the journal Nature Communications, has yet to be tested on a cosmic scale, but scientists have used the gelatinous material to print small shapes such as a circle, a square and a cone. They have also successfully programmed it to make materials with specific characteristics with other applications that could be useful in medicine.

Neel Joshi, associate professor of chemistry and chemical biology, works on programmable microbial ink for 3D printing of living materials in the Mugar Life Sciences Building. Photos by Matthew Modoono/Northeastern University

“We want to use living cells, microbes, as factories to make useful materials,” says Avinash Manjula-Basavanna, a postdoctoral fellow at Joshi's workshop and co-lead author on the new paper. The idea, he says, is to harness the properties unique to the materials that make up living things for a range of purposes, ranging from therapeutic to industrial.

“Think of it as a platform for building many different things, not just bricks for building or construction,” says Joshi. He explains the project by comparing it to how a polymer chemist thinks about how to devise plastic materials that can serve different purposes. Some plastics are hard and retain their shape, while others are flexible and soft.

“Biology is able to do similar things,” says Joshi. “Think about the difference between hair, which is flexible, and antlers on a deer or a rhinoceros or something. They are made of similar materials, but have very different functions. Biology has figured out how to tune these mechanical properties using a limited set of building blocks.”

The specific natural building block the scientists are exploiting is a protein produced by the bacterium E. coli. The material, called Curli fibers, is produced by bacterial cells as they attach to a surface and to each other to form a community. The same properties that make curli fibers a kind of glue for bacteria also make them an attractive material for microbial engineers like Joshi and his colleagues.

The researchers 3D printed small shapes using the microbial ink they developed from the bacterium Escherichia coli, also known as E. coli. Image courtesy of Duraj-Thatte et al., Nature Communications

To create the microbial connection, the scientists started by genetically engineering crops E. coli in a bottle. They fed the bacteria nutrients so that they would multiply and as they divided they would produce the desired polymers, the Curli fibers. The researchers then strained the gelatinous polymers and fed that material into a 3D printing device as a microbial ink.

Microbes have been used to make 3D printing ink before, but, say Joshi and Manjula-Basavanna, what sets this microbial ink apart is that it doesn't mix with anything else. Their gel is completely organic.

One of the perks of truly live material is that it's actually alive, says Manjula-Basavanna. And that means it can do what living things can do, like heal itself, like skin does. Under the right conditions, the cells in the microbial gel could simply do more than themselves.

It doesn't necessarily always increase, says Joshi. For example, if the cells stayed alive in the small cone the team made from the microbial gel, “if you took that whole cone and put it in some glucose solution, the cells would eat that glucose and make more of that fiber and grow the cone into something bigger,” he says. “There is the option to take advantage of the fact that there are living cells there. But you can also just kill the cells and use it as an inert material.”

While the original gel is made entirely of genetically modified E. coli, the researchers also tried mixing the ink with other genetically modified microbes with the goal of using the 3D-printed materials for specific purposes. So they made a material that could deliver an anti-cancer drug, which it released when it encountered a specific chemical stimulus. In another experiment, they also programmed another material to trap the toxic chemical Bisphenol A (BPA) when it encountered BPA in the environment.

“You could think about taking a bottle cap and printing our material on the inside of it, so that if there was BPA around, it would get absorbed by it and not be in your drink,” says Joshi.

This study was just a proof-of-concept attempt, but Joshi sees this microbial ink as opening a door to all kinds of possibilities for making things with biology.

“If there is a way to produce in a more sustainable way, it will involve using living cells,” he says. “This goes more towards this type of example of making things with living cells.”

For media inquiriescontact Marirose Sartoretto at m.sartoretto@northeastern.edu or 617-373-5718.