The robots hold chopsticks, spin platforms and look like snakes.

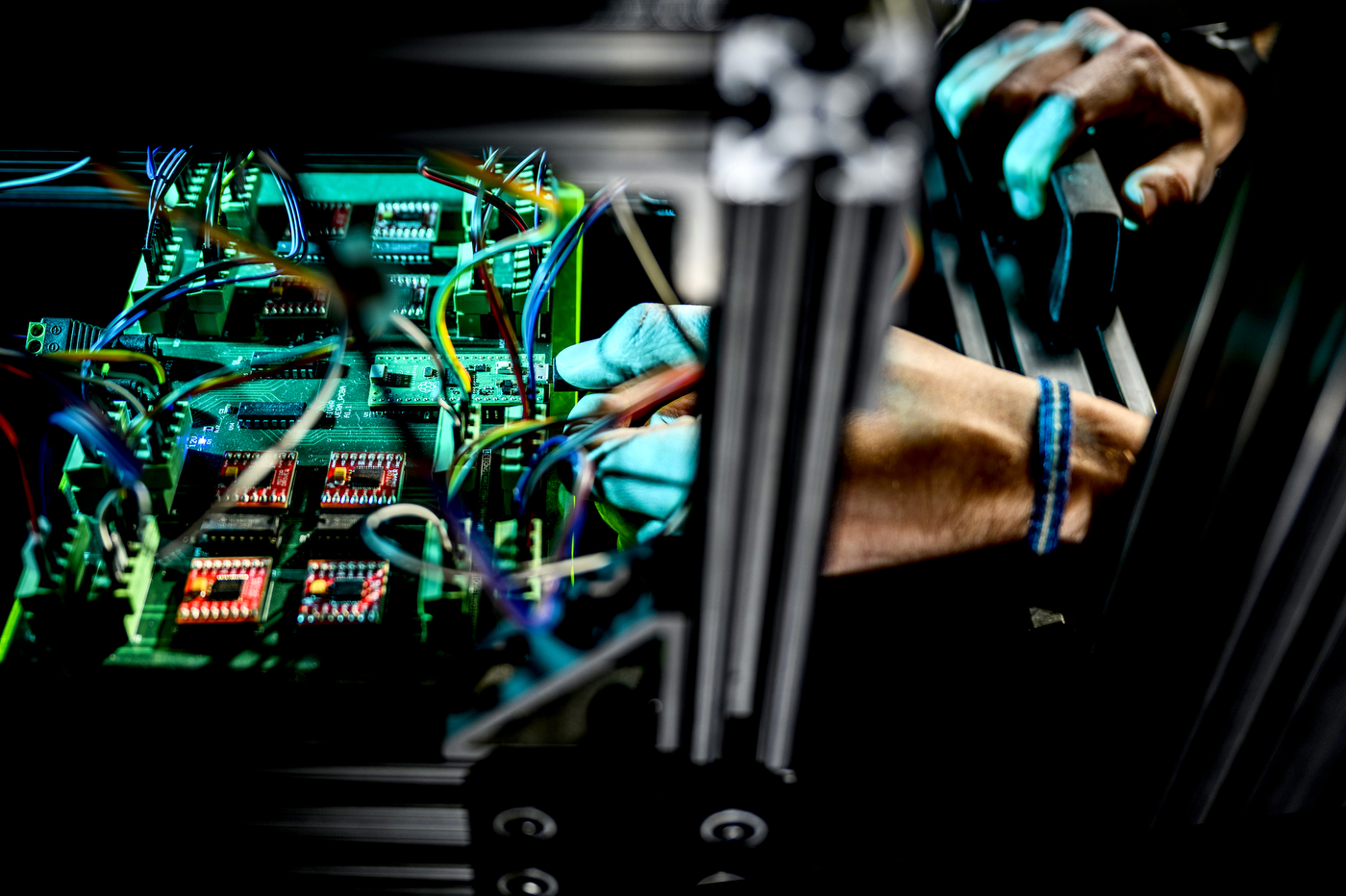

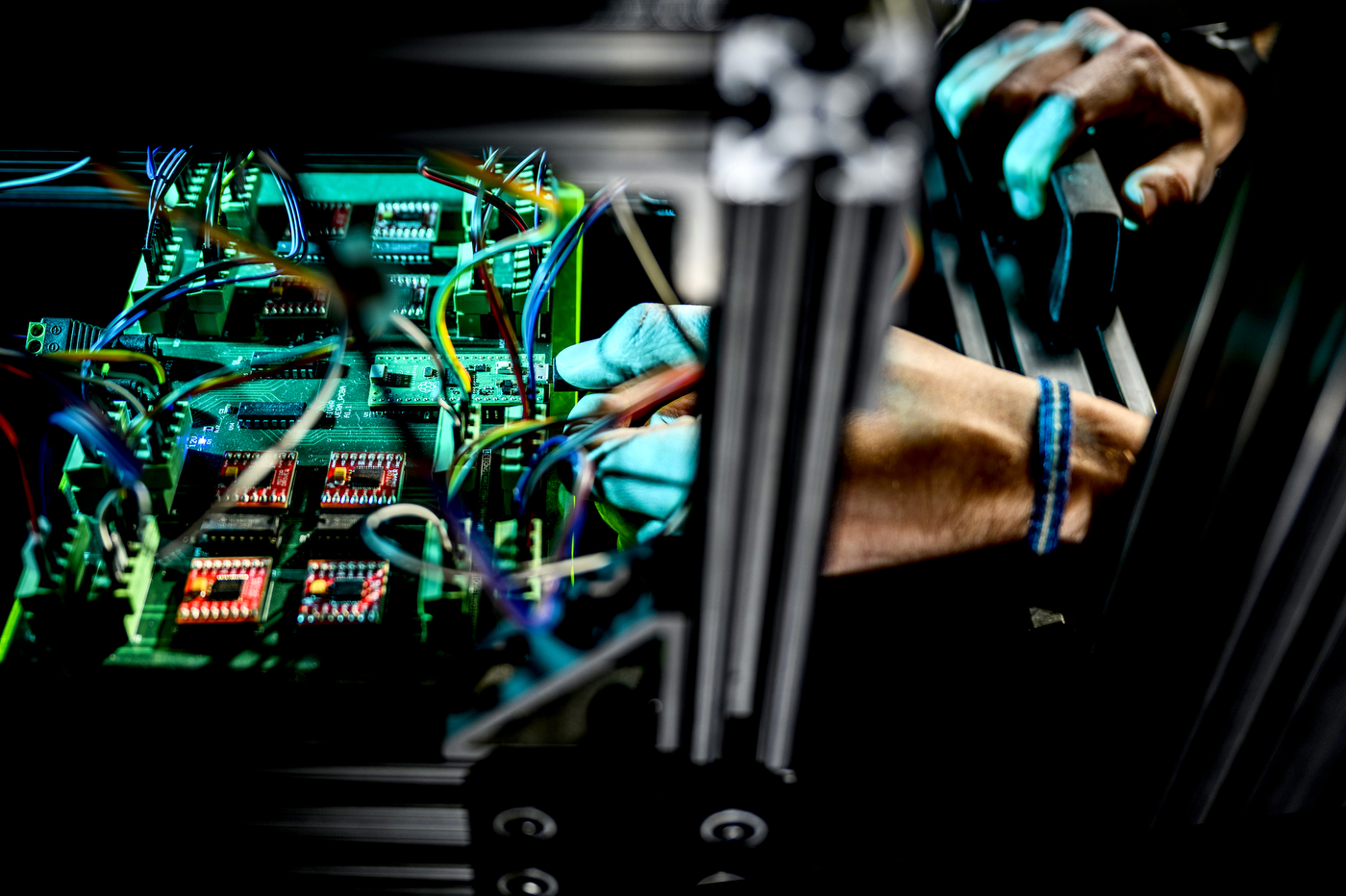

Roboticists in the Institute for Experiential Robotics lab in the new EXP building are conducting transformative research. Robots wield chopsticks for precise hand manipulation. Research continues with a snake-like robot created for NASA's BIG Idea Challenge that can navigate sandy environments like the moon. And the lab has fabrication rooms for electronics, 3D printing and laser cutting.

The new space occupies most of the first level of the eight-story science and engineering complex on the Boston campus. Its high bay is about the size of a basketball court — adorned with robotics systems that run the gamut of technology, including collaborative robots, industrial robot arms, mobile robots, drones, virtual reality systems and more.

The institute also has space on the seventh floor of the EXP that includes additional robots, as well as office and lab space for researchers to conduct their work.

“Our mission is simple in my mind — to enrich human experiences through meaningful growth and development of robotics technology,” says Taskin Padir, Northeastern professor of robotics and director of the institute.

“We've been working with the design team for the last six years, even before the renovation of the building,” he says. “We had a vision for the space where we can show what we mean by experiential robotics.”

Several Northeastern students and faculty in the lab work on projects led by Padir.

As part of a National Science Foundation grant, Northeastern developed a series of robotics applications designed to help workers in the seafood packaging industry use robots to move and pack products.

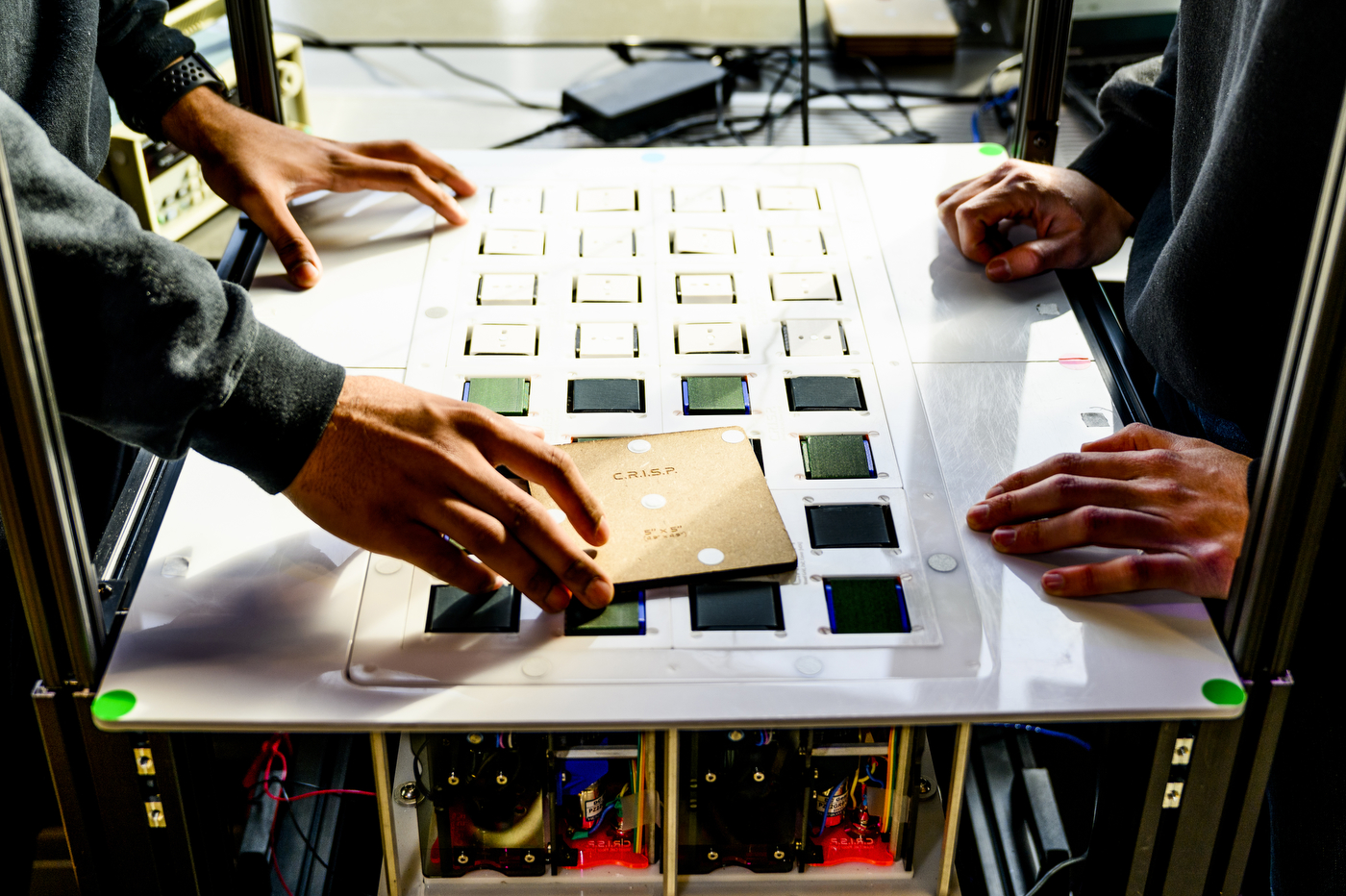

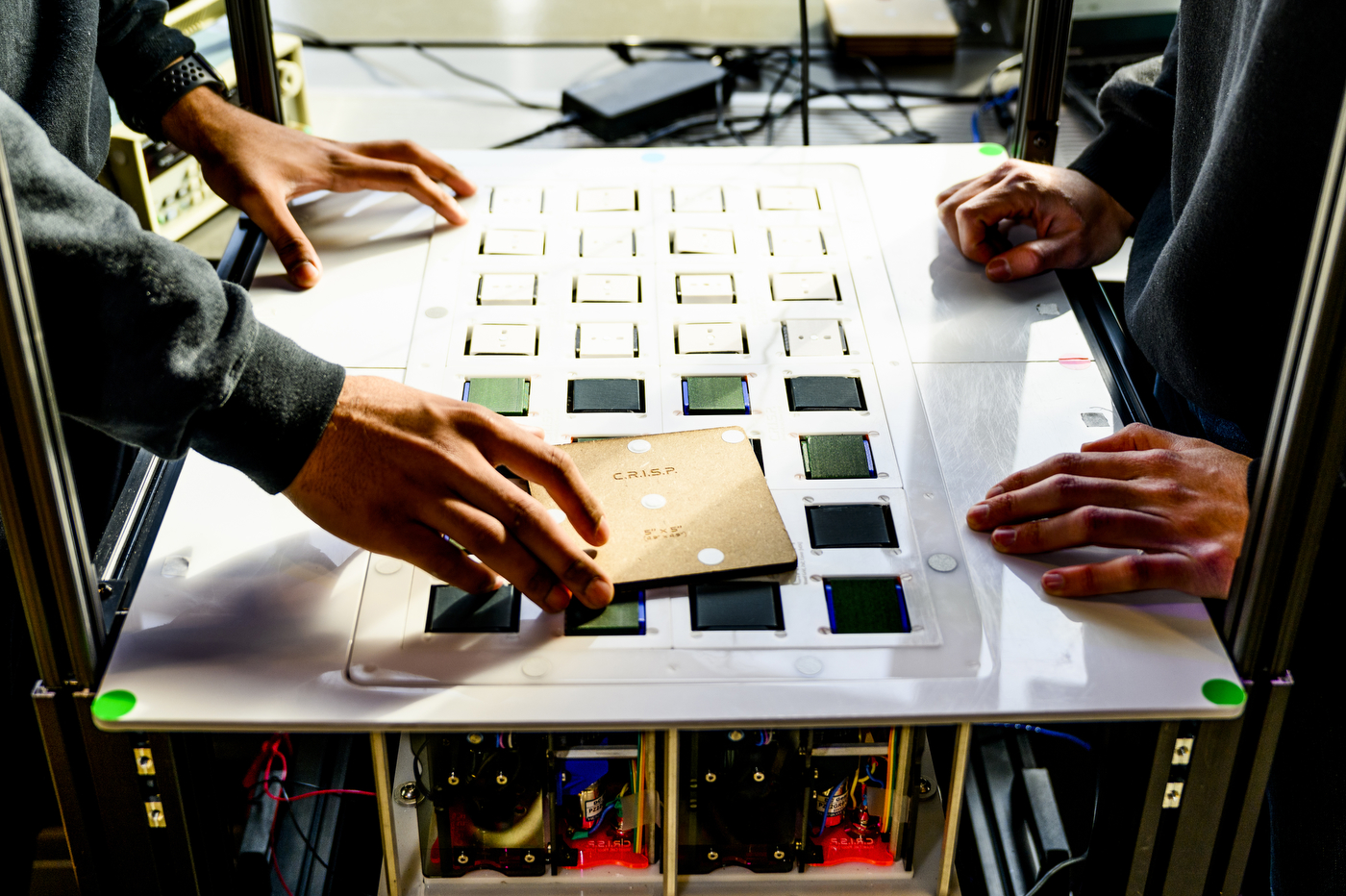

One of these systems involved the creation of a workstation that features an assistive robotic table. The name of the robotic system is VERA, which stands for voxel-enabled robotic assistant.

Embedded in the panel is a series of cube-like robotic devices called voxels. Voxels can be rotated to help move the position of an object, such as plastic packaging. The work cell also has a mounted camera to track the movement of an object.

“The idea here was motivated by us going to seafood production facilities and seeing people cutting very large fish like tuna and we noticed that they had a lot of trouble moving in certain places. That motivated us to design a robot that won't interfere with your workplace,” says Mark Zolotas, a researcher at Northeastern.

It's a bit different from what you'd expect a typical robotic workcell to look like, as no robotic arms are involved, he explains.

“We kind of see it as a general way of rethinking the way we look at robots in general,” Zolotas says.

So far, 20 faculty members working in various disciplines including robotics, artificial intelligence, computer science, physical therapy and entrepreneurship have a presence at the site, Padir says.

“It's not the space or the equipment that creates knowledge or pushes the boundaries of research,” says Padir. “It's the people. Without researchers we can do nothing. It works in a hierarchical way — we have professors who set the vision for the projects, and then we have full-time postdoctoral researchers who help guide the Ph.D. Students. We also have a very large group of graduate students in robotics. I envision them getting involved.”

“The institute also always provides experiential learning opportunities to our undergraduates. We have a history of recruiting qualified students to our institute, so they will be involved in our research,” adds Padir.

Hanumant Singh, professor of robotics at Northeastern, has several robots housed in the lab, including robots designed for underwater use. He says one of the lab's key innovations is that it allows robotics researchers to collaborate in a shared space.

“The biggest and most important part of this is that we work as collaborators,” says Singh, who notes that the lab's large open space allows for modularity and allows researchers to use it however they see fit. “It's an open space that doesn't belong to anyone that can be reconfigured based on the project and the people working on things.”

Julie Marble, executive director of the institute, echoed Singh's sentiment.

“One of the main goals of the Institute for Experiential Robotics is to become the flagship for robotics at Northeastern,” says Marble. “If you want to have robotics at this level, you have to be not only interdisciplinary but you also have to have a lot of collaboration. One of the goals of this space is to create a space where all of our faculty and their alumni can work collaboratively.”

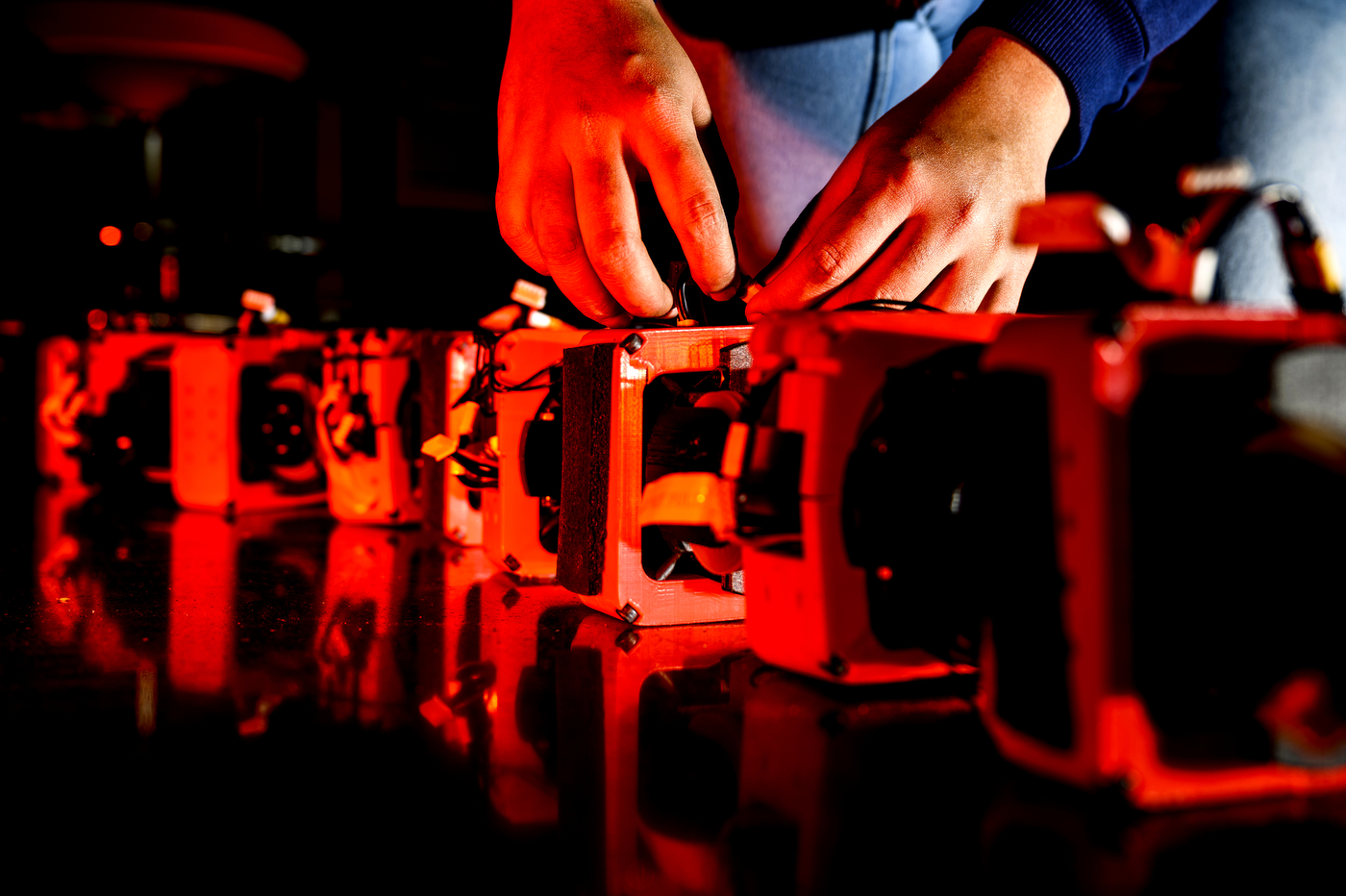

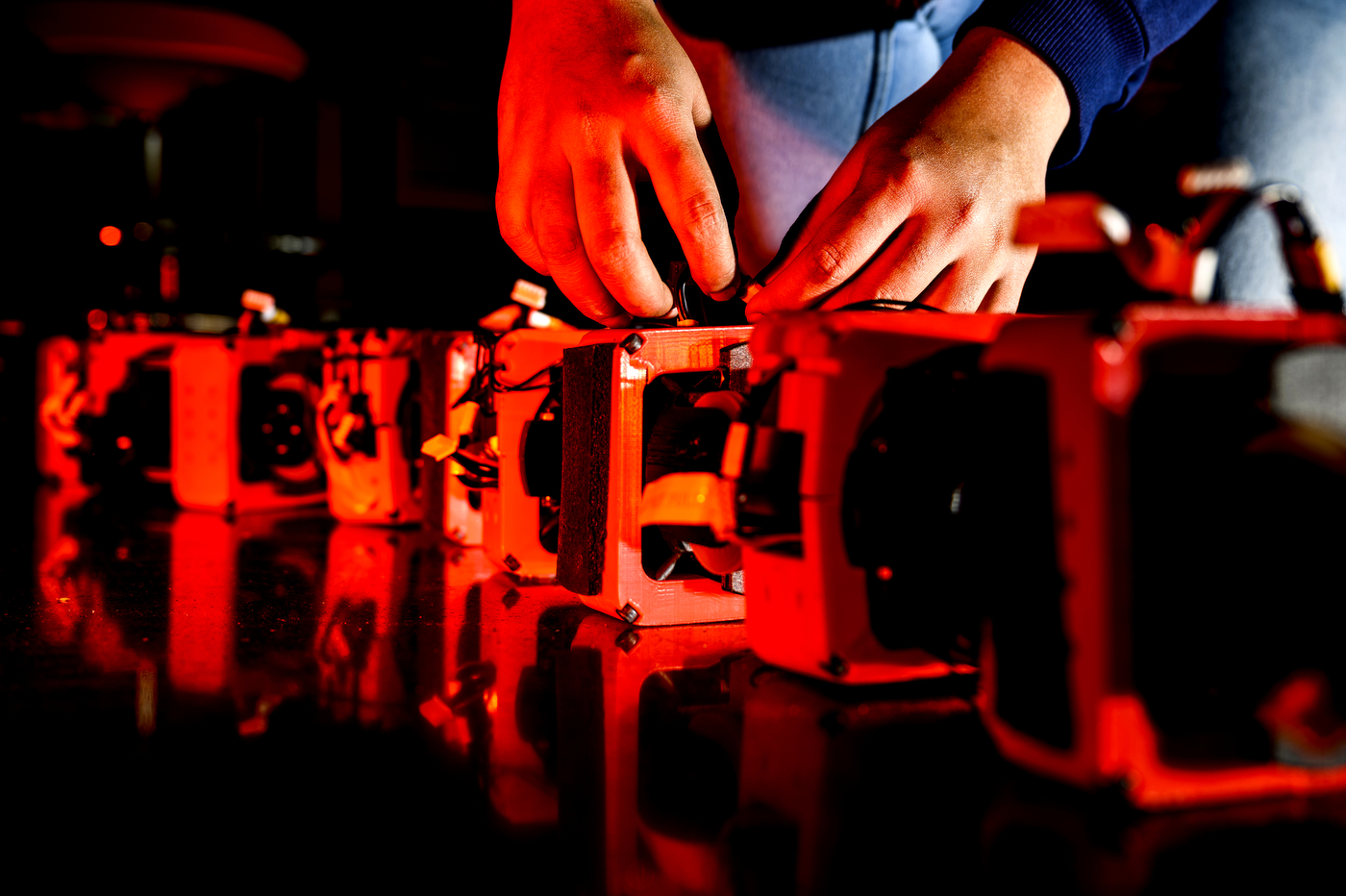

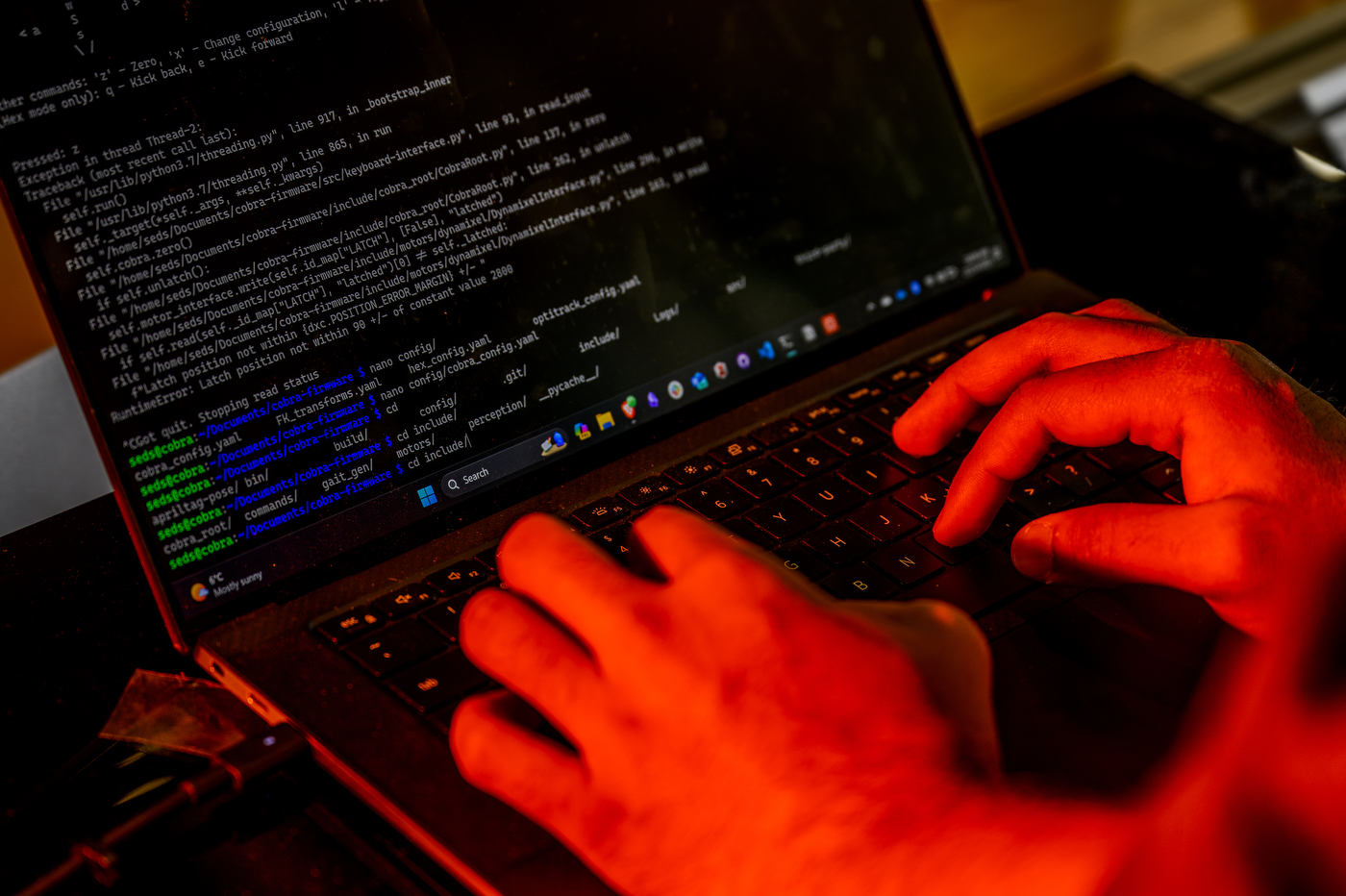

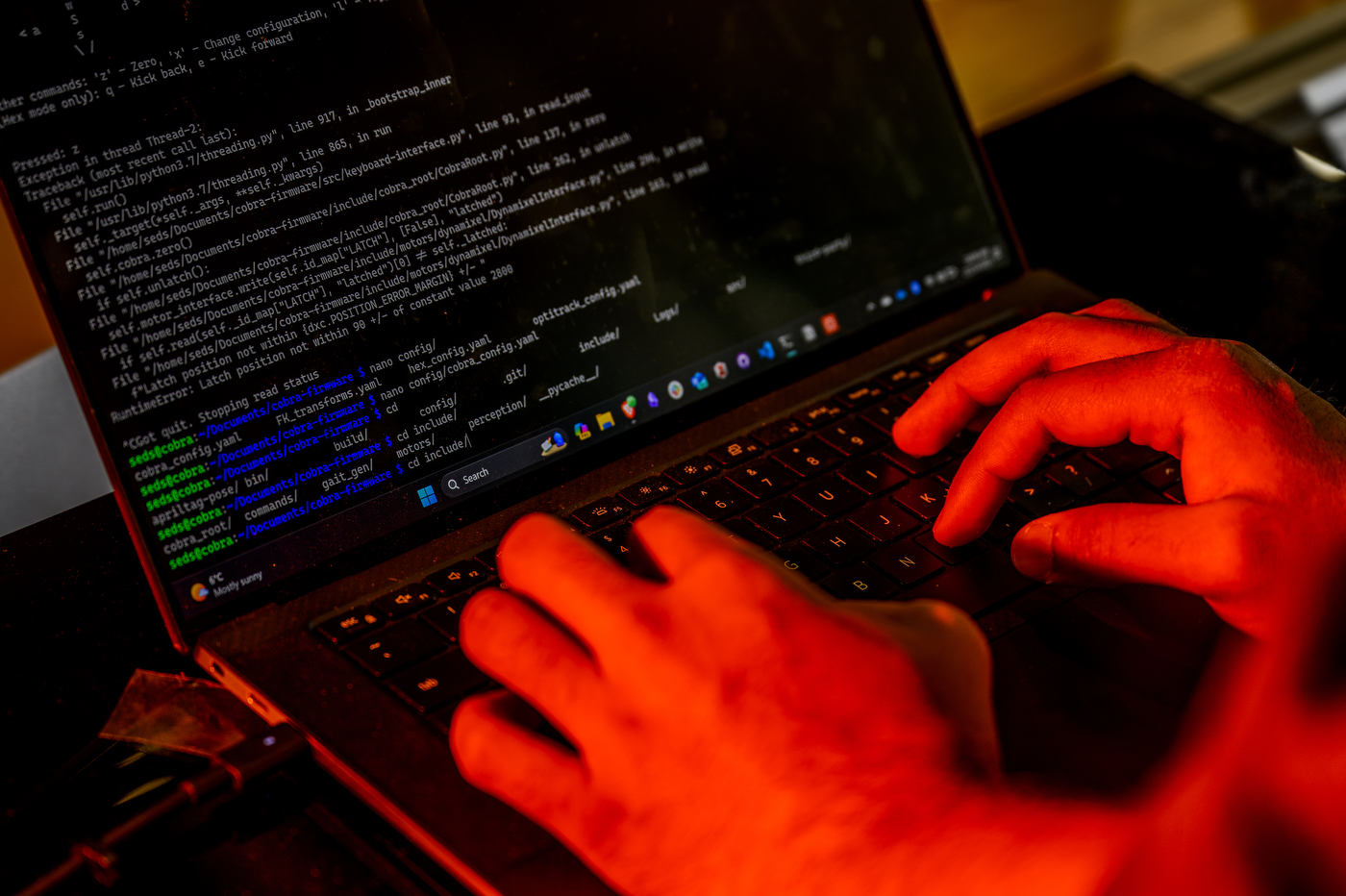

PhD students Adarsh Salagame and Kruthika Gangaraju are certainly taking advantage of the space. They were part of the team behind the COBRA system, or the Crater Observing Bio-inspired Rolling Articulator.

Our mission is simple in my mind — to enrich human experiences through meaningful growth and development of robotics technology.

Taskin Padir, Northeastern robotics professor and laboratory director of the Institute for Experiential Robotics

The snake-like robot was created for NASA's BIG Idea Challenge, which invited teams of students to develop a robotic system designed to navigate difficult terrain. Alierez Ramezani, a Northeastern assistant professor of electrical and computer engineering, led the team that developed the project. The goal was to develop a robot that could operate at the lunar south pole.

They turned to nature for a solution, Salagame says.

“Snakes are well documented to be able to function in these sandy environments,” Salagame says after demonstrating the robot for Northeastern Global News. “Other standard robots don't work in these kinds of environments, so that's where the snake movement came in.”

A remarkable aspect of the CORBA system is its ability to connect both ends to create a perfect circle, which allows it to easily descend hills while using little energy, Marble explains.

“It can travel an extremely long distance without losing any power,” he says.

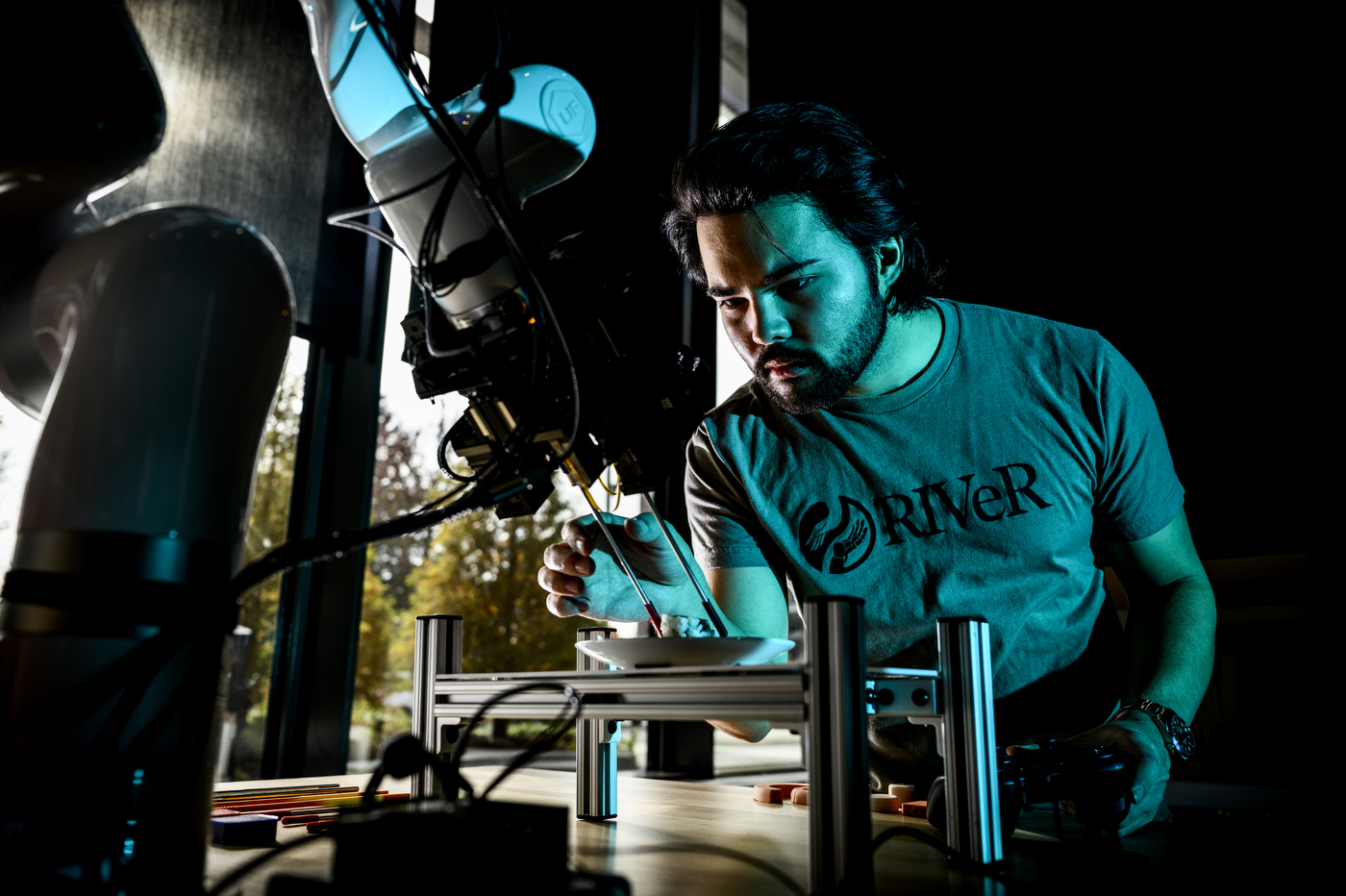

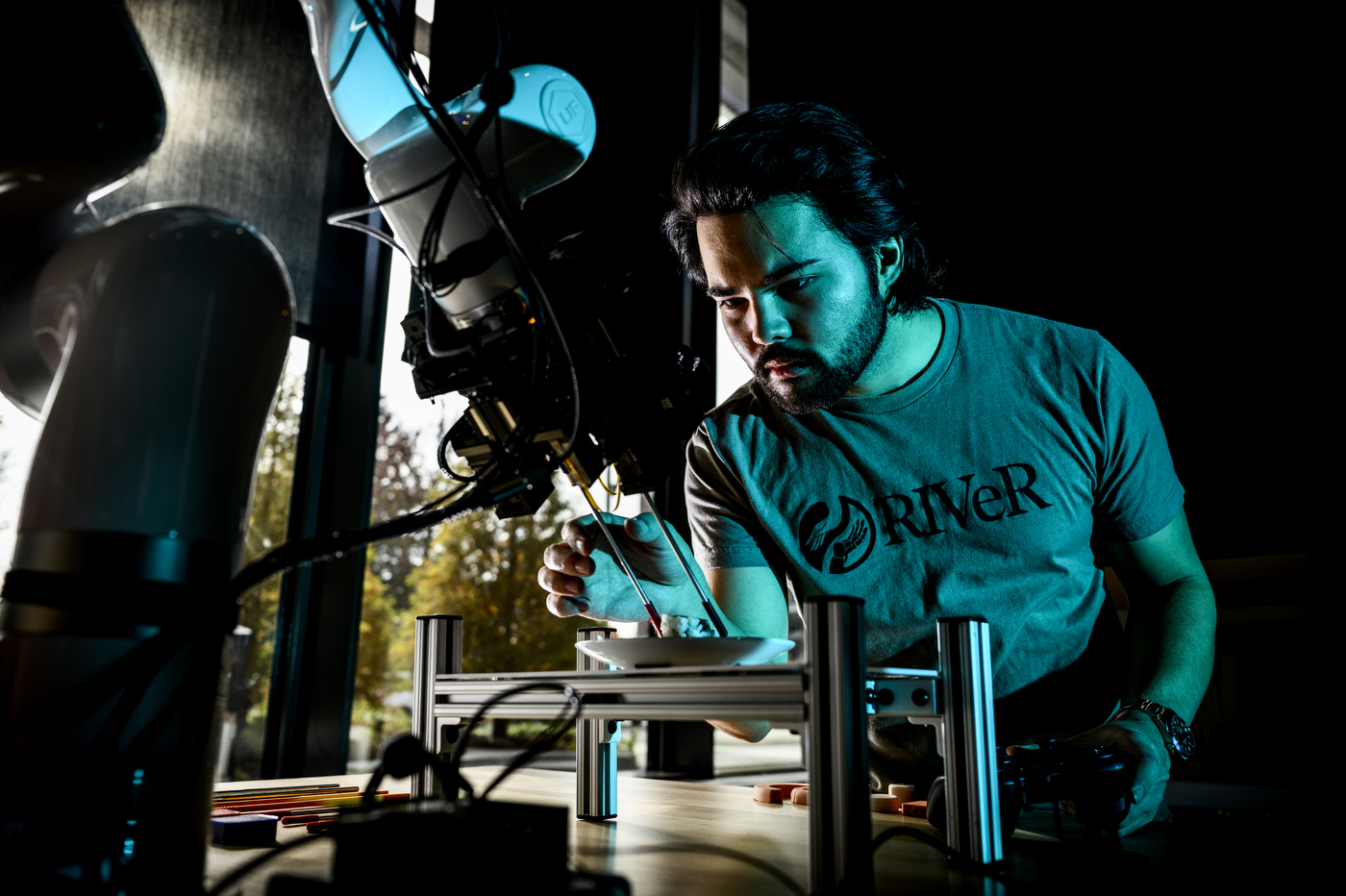

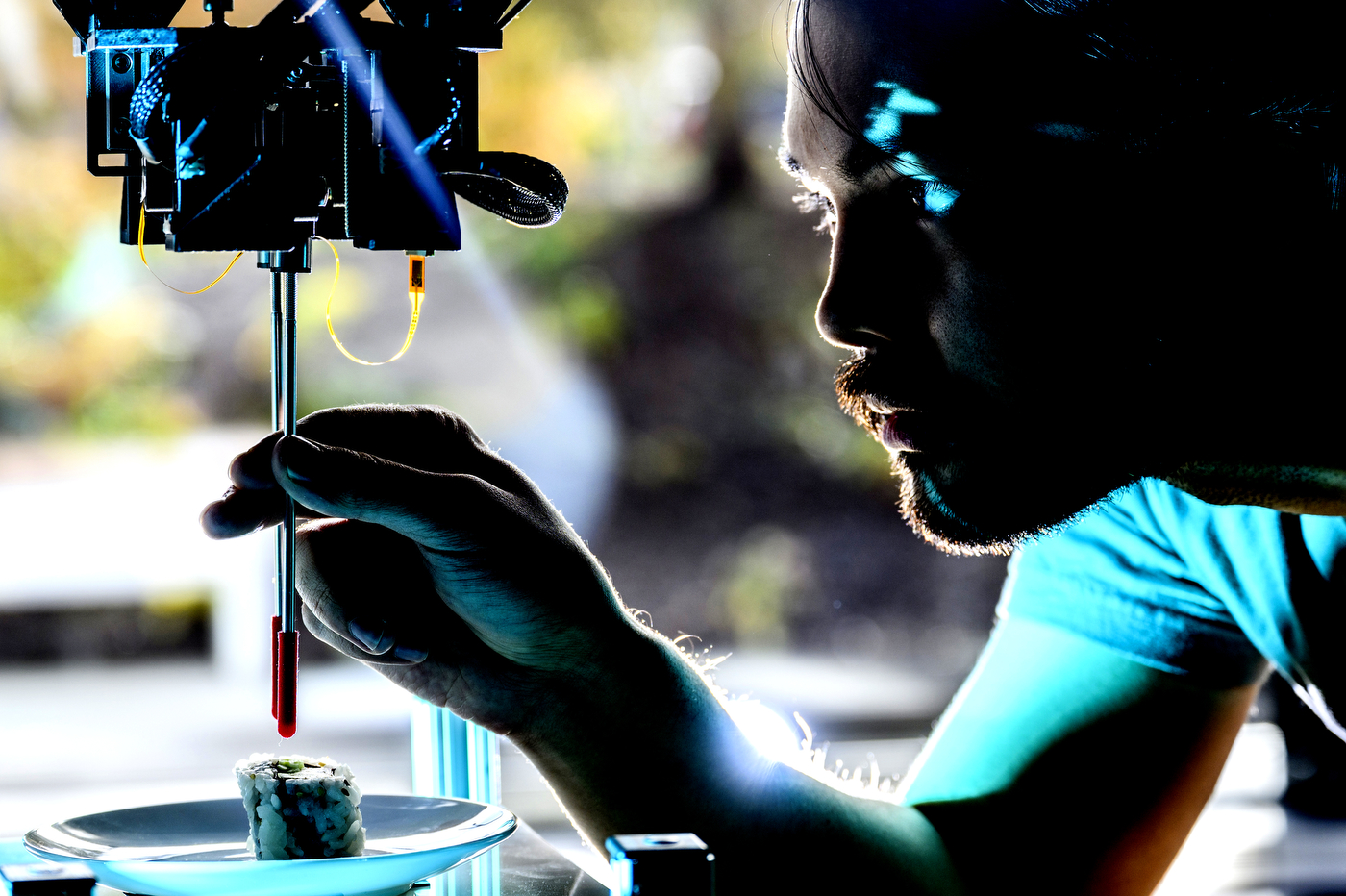

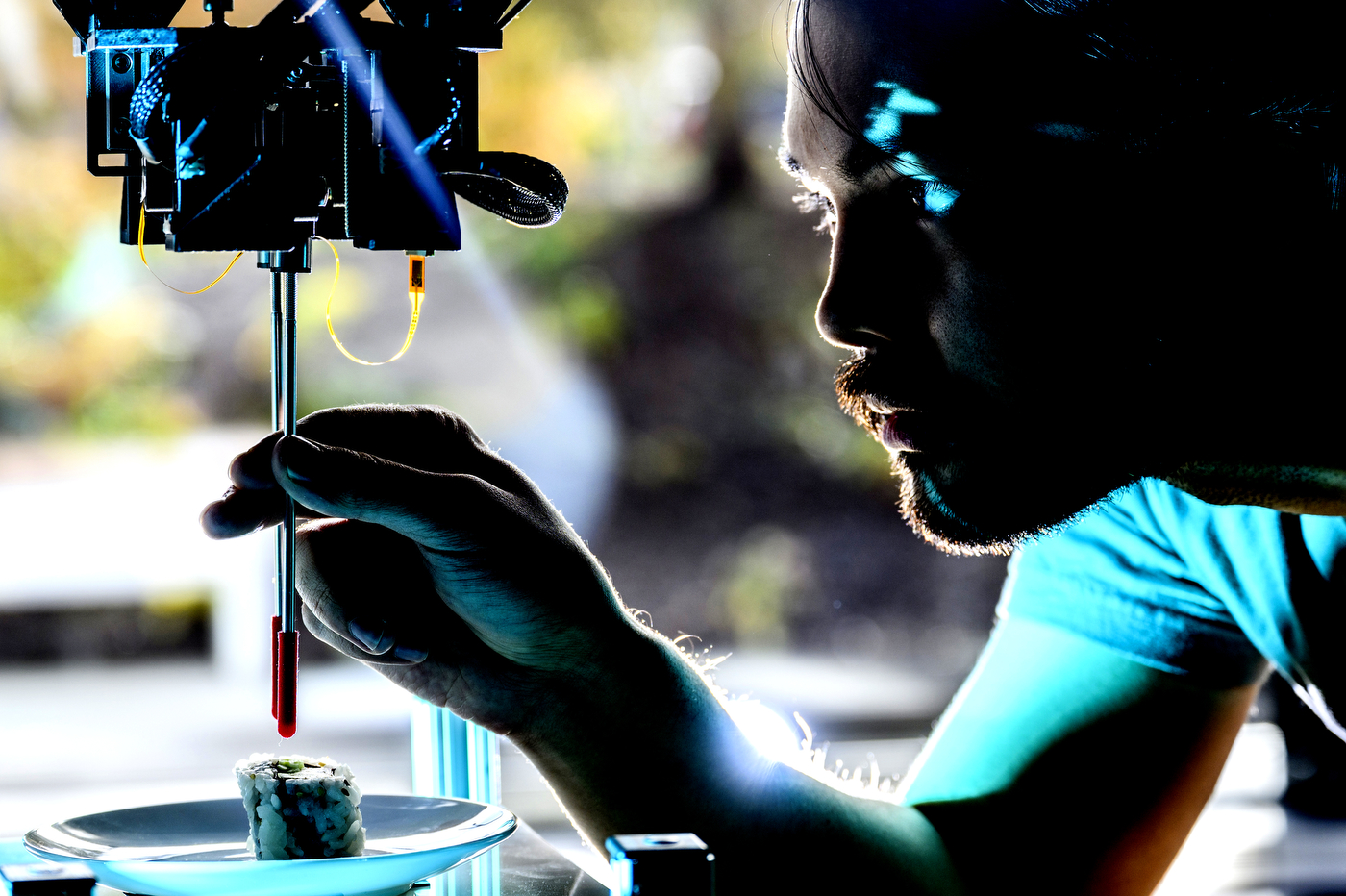

Austin Allison is another of Padir's students exploring using robotics to package seafood. A PhD student studying bioengineering, he is part of the research team that created HASHI, or the highly adaptable seafood handling instrument.

In a demonstration for Northeastern Global News, Allison showed the robotic system in action, which consists of a robot arm and tools at the end of the arm that look like chopsticks. (Hashi is also the Japanese word for chopsticks.)

The robot is designed to handle, handle and move small pieces of fish food like sushi, he says. And what's the best way to handle sushi? With chopsticks, of course.

“We thought, 'Well, there's probably been thousands of cultures and billions of people throughout history that have used chopsticks not just for sushi but to cook whole meals,'” he says.

Allison says each chopstick component has three degrees of freedom and can be controlled using a video game controller. Robot chopsticks can handle objects in the hand quite easily. Ideally, this system would be used to package pre-prepared meals (think lunches for example).

“There's a term in robotics called hand manipulation, which is if you want to think of picking something up and doing it like a pinch and roll,” he says. “It's interesting to be able to do it on a small scale.”

Allison emphasized that the new robotics lab was a great addition and he likes that he now has more space to do special research.

“Our offices are a little more separated from the loud distracting machinery and the larger hardware that's on the first floor,” he says. “We also have more dedicated rooms for manufacturing, such as a dedicated machine shop, an electronics/3D printing/laser cutting room, etc.”

As he moves toward his Ph.D., Allison says he's excited to see more of what's on offer at EXP.

“Future access to some of the previously unavailable tools on the first floor of EXP (waterjet cutter, CNC router and mill, welding, etc.) will allow me to efficiently prototype and create more advanced hardware for future projects and endeavors robotics”. he adds.

Cesareo Contreras is a reporter for Northeastern Global News. Email him at c.contreras@northeastern.edu. Follow him on X/Twitter @cesareo_r and Threads @cesareor.